Perfect Equipment. India

Perfect, a company born from technological expertise four decades ago, remains dedicated to delivering exceptional engineering solutions. This dedication to uncompromising quality and continuous innovation has earned Perfect the trust of global textile leaders. Explore more about http://www.perfectequipments.com/

Products:

Card wire service mcs

Perfect Equipments specializes in manufacturing and servicing machinery for card room maintenance, a crucial aspect of textile production. Their “card wire service” pertains to the maintenance of the wire clothing on carding machine cylinders and flats. This includes services and machines that assist in wire unwinding, mounting, and grinding.

Products

- Automatic Flat Grinding Machine – AFG 3

- Flat Clipping Machine – PFC 4

- Flat End Milling Machine – FEM 2

- Roller Wire Mounting Machine – RMM 1

- Butt – Welder

- Wire Unwinding Machine

- Reciprocating Stone Grinder

- On Card Flat Grinding Roller – OCFG 1

Roll shop service mcs

Roll shop service MCS Perfectequipments signifies a specialized offering focused on the maintenance and upkeep of industrial rolls. These rolls are critical components in various manufacturing processes, such as those found in steel, paper, and textile industries. Perfectequipments provides machinery and services designed to ensure these rolls maintain optimal performance. This includes services like grinding, repair, and overall maintenance, which are essential for preventing downtime and ensuring product quality.

Products

- Automatic Cot Grinding Machine – ACG 600 EL

- Automatic Cot Grinding Machine – ACG 2

- Twin Head Twin Feeding Cot Grinder – TWG – TF

- Twin Grinder – TWG

- Cot Grinding Machine – BM – 1 AF

- Cot Grinding Machine – BM – 1

- Cot Grinding Machine – MM – 2

- Cot Grinding Machine – SM – 3

- Fully Motorized Cot Checking Device – FMCC

- Cot Checking Device – CCD

- Shore Hardness Tester

- Cot Mounting Machine / Press – CMHY – V

- Hand Operated Greasing System for Arbour – HARG

- Automatic Arbour Flushing Machine – ARF 1

- Automatic Arbour Flushing Machine – ARF 8

- Spindle Lubricating Machine with 3 tank – SL3

- Horizontal Hydraulic Cot Mounting Machine – CMHY – H

- Hand Cot Mounting Machine – MCM – 4

- Cot Mounting Pneumatic Machine CMPT

- Automatic UV Treatment Machine – UVT – OL

-

- Ultra Violet Treatment Machine – UVTM

- Automatic Arbour Greasing Machine – ARG

- Ultimate Flyer Cleaning Machine – HOT CLEAN HP20

- Hydraulic Fluted Roller Truing Machine – FRTH

- Manual Fluted Roller Truing Machine – FRTM

- Clearer Roller Cleaning Machine – CRCS – AF

- Clearer Roller Cleaning Machine – CRCS

- Roving Stripping & Opening Machine – ROS

- Roving Waste Opener – RWO

Hard and Soft waste lines

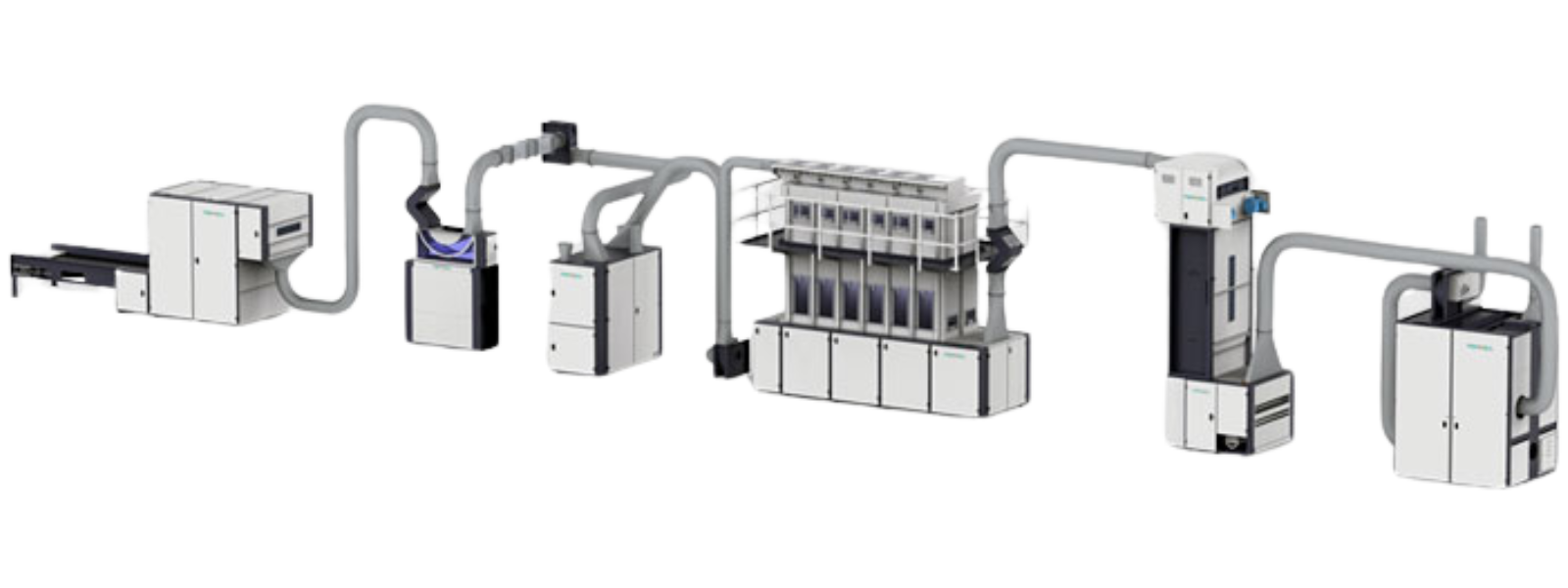

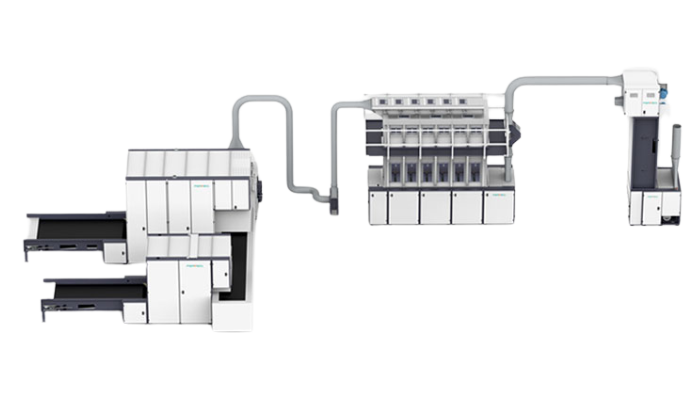

The PRT 1000 Hard Waste & Fabric Opening Line offers a versatile solution for processing various spun yarn hard waste materials. This comprehensive system can be tailored to meet specific production needs, with configurable capacities ranging from 60 kg/h to 240 kg/h. Designed for flexibility, the line’s modular construction allows for adaptable placement within existing facility layouts, maximizing space utilization.

Perfect Equipment specializes in providing comprehensive solutions for processing soft waste within the textile industry. Their soft waste lines are designed to efficiently recover and recycle valuable fibers from various textile byproducts, minimizing waste and maximizing resource utilization. These systems typically incorporate a series of machines that work in conjunction to open, clean, and process soft waste materials.

Non woven lines

Automatic Blending Line

An automated blending line efficiently and accurately combines two or more distinct materials, such as cotton, synthetics, blends, nonwovens, recycled fibers, or surgical cotton, through automatic weighing and mixing processes. This system ensures a high degree of precision in achieving the desired blend percentages, resulting in consistent and reliable product quality. The production capacity of these lines can reach up to 750 kg/h, varying based on the specific blend proportions being processed, making them a versatile solution for diverse manufacturing needs.

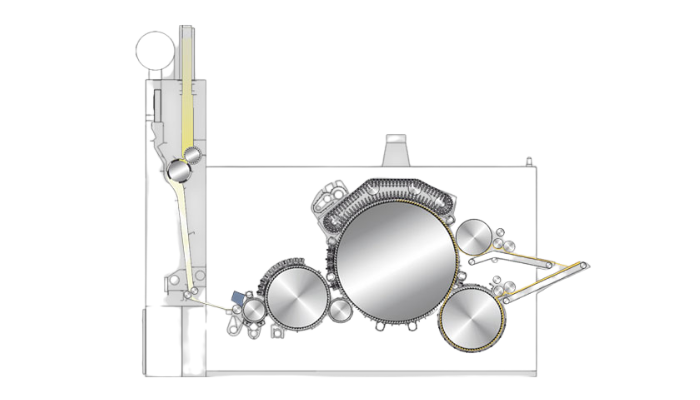

Card 1275 BDD

The Card 1275 BDD, designated by product code Card 1275 BDD, is a specialized carding machine designed for cotton and synthetic spunlace production lines. This high-performance card is optimized for producing webs with outputs reaching up to 40 GSM, delivering high productivity output that aligns perfectly with the demands of modern spunlace manufacturing.

Medical Cotton lines

Perfect Equipments PVT focuses on delivering reliable and efficient medical cotton lines that adhere to strict quality control measures, ensuring the production of safe and high-quality medical cotton products. They also emphasize on the ability to customize the lines to meet the individual needs of their customers.

Perfect Equipments PVT specializes in designing and manufacturing complete medical cotton lines, catering to the stringent hygiene and quality requirements of the medical industry. These lines are engineered to transform raw cotton into sterile, absorbent cotton products used in medical applications. The process typically involves several key stages:

- Bale Opening and Cleaning: Raw cotton bales are opened and thoroughly cleaned to remove impurities and foreign matter.

- Carding: The cleaned cotton is then carded to align the fibers, creating a uniform web.

- Lap Formation: The carded web is formed into laps, which are then processed further.

- Bleaching and Purification: The cotton undergoes a rigorous bleaching and purification process to achieve the necessary sterility and whiteness.

- Drying and Sterilization: The purified cotton is dried and sterilized to eliminate any remaining microorganisms, ensuring it meets medical-grade standards.

- Cutting and Packaging: The sterilized cotton is then cut into desired sizes and packaged according to specific requirements.

Spinning Blowroom & Card Recycling

Perfect Equipment Pvt. Ltd. provides comprehensive solutions for spinning blowroom and card recycling,

addressing the critical need for efficient waste management within textile spinning mills.

Their systems are designed to recover and repurpose valuable fibers from blowroom and carding waste,

minimizing waste disposal and promoting sustainable practices.